2110 CAPACITANCE ENCODER

2110 CAPACITANCE ENCODER

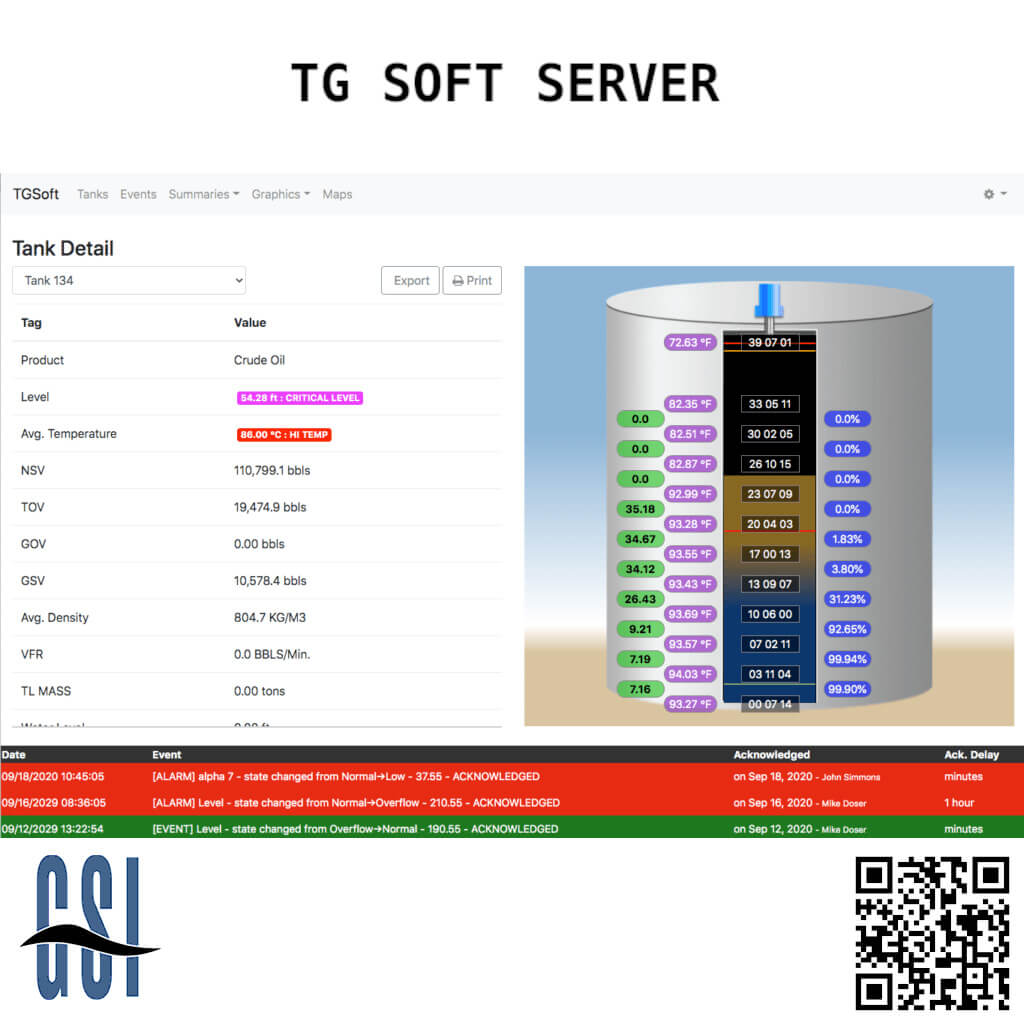

The GSI-2110 Capacitance Encoder provides transmission of mechanical tank gauge data and I/O from tank side to a communication interface or host system.

TECHNICAL DETAILS

The transmitter mounts to a mechanical tank gauge, through a coupling assembly, and uses the direct linear input movement of the gauge to convert to a digital level output. An RTD connected will supply the temperature of the tank product. The Capacitance Encoder consists of three major components:

- Transmitter housing

- Encoder

- Transmitter Board

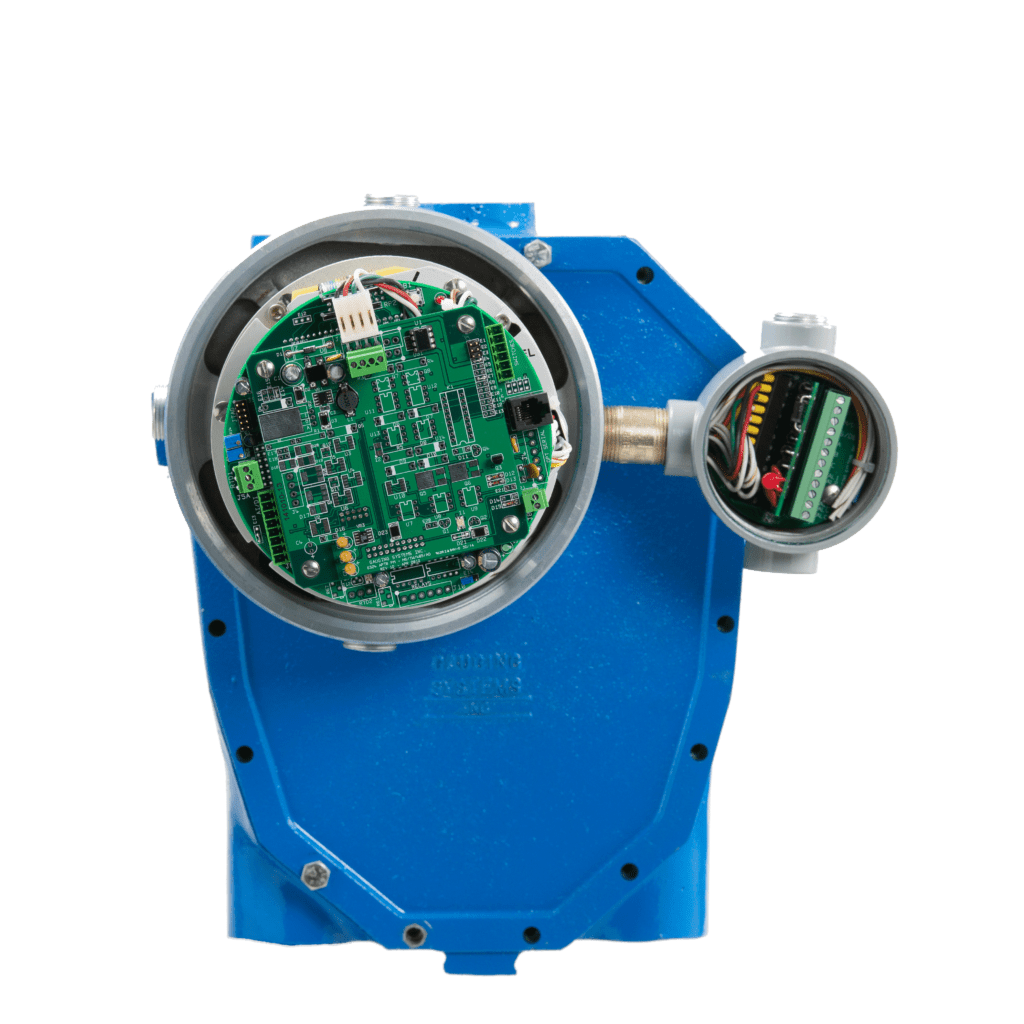

Transmitter Housing

This is an explosion proof (NEMA 7) cast aluminum housing with wiring nipple assembly and J-condulet for field wiring terminations and optional surge protection. The transmitter housing is mechanically designed to couple directly to a GSI, Protectoseal, Motherwell or Varec mechanical tank gauge. With an optional coupling box, the transmitter housing will couple with various other mechanical tank gauges, such as L & J, Whessoe, etc.

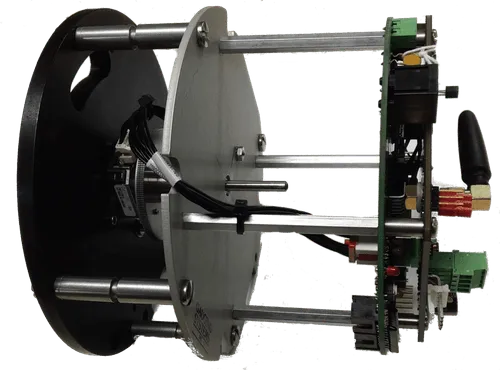

Transmitter Encoder

GSI designed the 2110 Capacitance Encoder to be the most reliable and accurate encoder on the market. The 2110 eliminates problems found within other manufacturers’ brush and optical (absolute & non-absolute) encoders. Some manufacturers’ products still include parts such as Geneva gears, Two zero points on their Inch disk, one direction brush control, reflective code disks and optical diodes, hall effect encoders, etc. that are more maintenance intensive. The GSI 2100 is an Absolute encoder, if it losses power and is repowered the level indication remains the same. If a non-absolute encoder losses power (battery) it loses the level prior to power loss. Consequently, non-absolute transmitters have been known to have caused major spills (Overfill).

API Standards

As for API Chapter 3.1A and 3.1B, the manual reference hand line used for verification of automatic tank gauges is in 1/16” increments. Our mechanical tank gauges also measure in 1/16” increments with verifiable and repeatable accuracy.

Transmitter Board

The 2110 Capacitance Encoder supports a number of protocols and topologies for new applications or for integration and retrofit of existing systems. For new applications please consult GSI on the required protocol and topology for the application.

For integration and retrofit applications GSI has transmitter boards designed to meet field power requirements, electrical standard, protocol, and communication topology of your existing system. GSI manufactures field proven transmitter boards to match open standards such as MODBUS RTU / RS485 or vendor dedicated protocols such as Varec® Mark-Space / 48Vdc, L&J Technologies® Tankway /38-70Vdc, GPE TP600, and other manufacturers’ forms of non-compliant MODBUS / 220Vac – 24Vdc.

Note: GSI standard protocol is MODBUS RTU over an RS 485 bus

APPLICATIONS WHEN USED WITH A MECHANICAL TANK GAUGE

- Liquid Level Measurement

- Temperature Measurement

- I/O

7 Analog or Digital Inputs, 2 Analog Outputs, 2 Form C Discreet Outputs

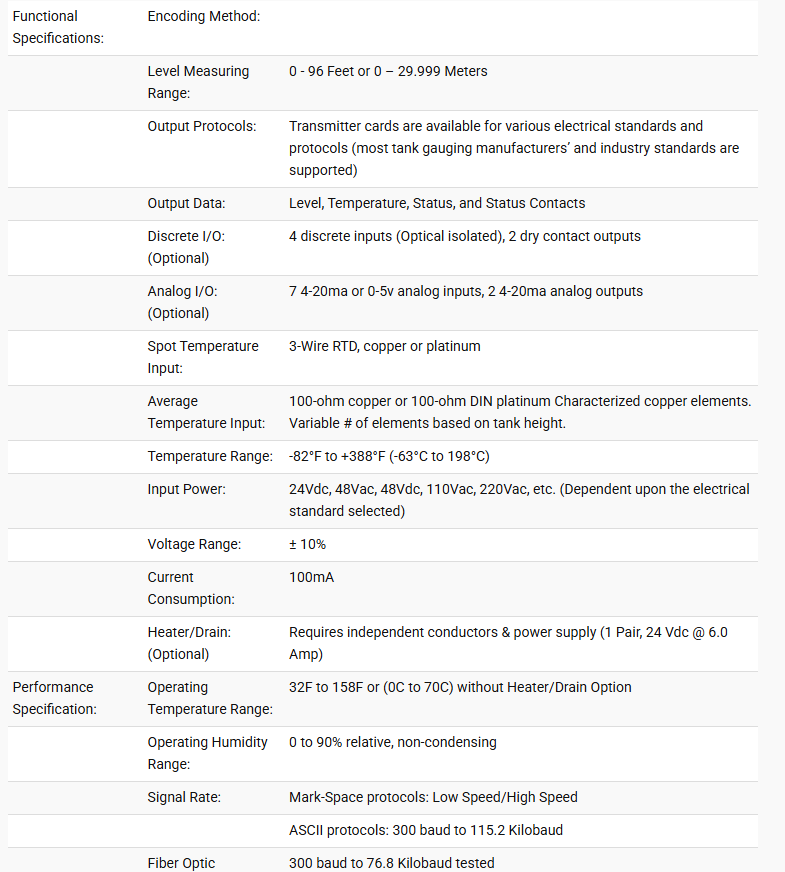

SPECIFICATIONS